Korea MFDS Certificate

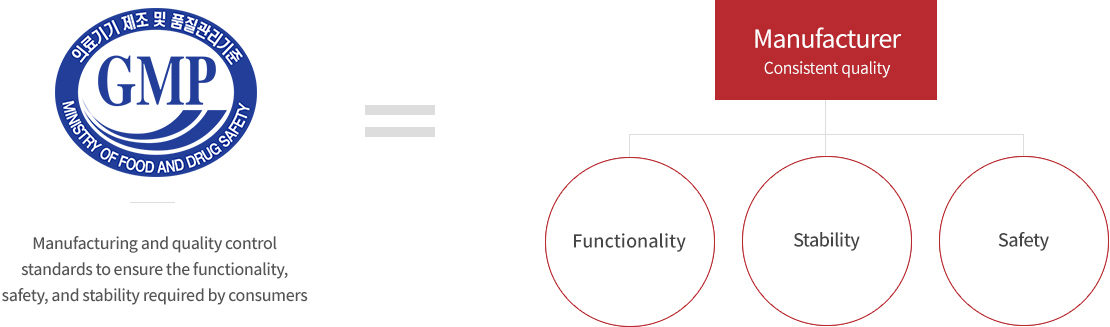

GMP

GMP stands for Good Manufacturing Practice, which sets the minimum standards to guarantee the safety and effectiveness of medical devices. It is one of the standards for the quality management system that stipulates what must be followed to guarantee the quality of medical devices throughout all processes fromthe development of medical devices to the purchase of raw materials, manufacturing, inspection, packaging, installation, storage, shipment, and claims or returns.

In other words, it is the minimum requirement to establish a quality management system that can ensure that medical devices produced and sold by medical device companies are consistently manufactured and sold as safe and effective quality suitable for their intended use. In Korea, manufacturers should establish a quality management system under Paragraph 4 of Article 6 (Manufacturing Business Permission, etc.) of the Medical Device Act, Paragraph 4 of Article 13 (Obligations of Manufacturers), Article 15 of the Enforcement Regulations of the same Act (Import Business Permission, etc.) and Article 20 of the Enforcement Regulations of the same Act (Matters to Be Observed by Importers) and follow the 'Medical Device Manufacturing and Quality Control Standards' announced by the Minister of Food and Drug Safety when they are evaluated for conformity.

As it has been scientifically revealed that healthy functional foods play a very important role in the prevention of chronic degenerative diseases caused by diet and promotion of national health, and there is a need for scientific proof and operation management system for the safety and functionality of health supplements, etc., and the demand for health functional food industry increases, there have been negative cases of using loopholes in the manufacturing and distribution regulatory system of health functional foods (health supplements, nutritional supplements among special nutritional foods, ginseng products, etc.) under the Food Sanitation Act. As the need for stricter national supervision in the manufacturing and distribution process of health functional food was raised, the ‘Health Functional Foods Act’ was enacted and promulgated (August 26, 2002) and enforced (January 2004) to promote the safety of health functional food. Since enforcement, the development of the health functional food industry applying cutting-edge life science and technology has been promoted.

- An increase in corporate competitiveness and sales

- Improvement of internal and external reliability of the company

- Establishment of practical countermeasures for PL and provision of the basis for implementation

- Improvement of workplace buildings and facilities and improvement of limitations such as productivity and manageability

- Improvement of worker and manager awareness and quality improvement

- Development and operation of on-site document management systems and forms

- - An increase in corporate competitiveness and sales

- - Improvement of internal and external reliability of the company

- - Establishment of practical countermeasures for PL and provision of the basis for implementation

- - Improvement of workplace buildings and facilities and improvement of limitations such as productivity and manageability

- - Improvement of worker and manager awareness and quality improvement

- - Development and operation of on-site document management systems and forms